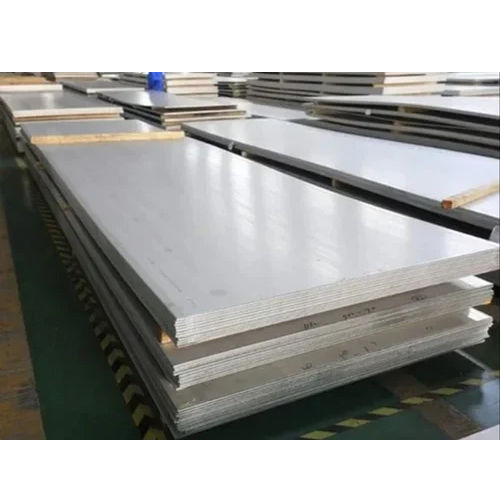

Monel 400 Plate

Monel 400 Plate Specification

- Thermal Conductivity

- 21.8 W/mK

- Tensile Strength

- 517 MPa

- Hardness

- 75 Rockwell B

- Thickness

- Various (as per requirement)

- Product Type

- Plate

- Types of Alloy

- Nickel-Copper

- Material

- Nickel-Copper Alloy

- Shape

- Rectangular

- Strength

- High mechanical strength

- Resistance

- Excellent resistance to corrosion and acids

- Grade

- Monel 400

- Melting Point

- 13001350C

- Density

- 8.8 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Ni 63% Cu 30% Fe 2.5% Mn 2% Si 0.5% C 0.3% S 0.024%

- Color

- Silver

About Monel 400 Plate

FAQs of Monel 400 Plate:

Q: What are the key features of Monel 400 Plate?

A: The Monel 400 Plate is known for its excellent resistance to corrosion and acids, high mechanical strength, and a density of 8.8 g/cm3.Q: What is the chemical composition of Monel 400 Plate?

A: The Monel 400 Plate is primarily composed of Nickel (63%), Copper (30%), Iron (2.5%), Manganese (2%), Silicon (0.5%), Carbon (0.3%), and Sulfur (0.024%).Q: What is the shape of the Monel 400 Plate?

A: The Monel 400 Plate comes in a rectangular shape, making it easy to handle and suitable for various applications.Q: What is the melting point of Monel 400 Plate?

A: The melting point of Monel 400 Plate ranges from 1300 to 1350C, providing stability in high-temperature environments.Q: What industries can benefit from using Monel 400 Plate?

A: Industries such as marine, chemical processing, oil and gas, and aerospace can benefit from the versatile properties of Monel 400 Plate.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Monel Products Category

Monel Tube Fittings

Density : 8.8 Gram per cubic centimeter(g/cm3)

Thickness : Standard pipe fitting thickness

Shape : Other, Elbow

Melting Point : 13001350C

Color : Silvery metallic

Strength : High mechanical strength

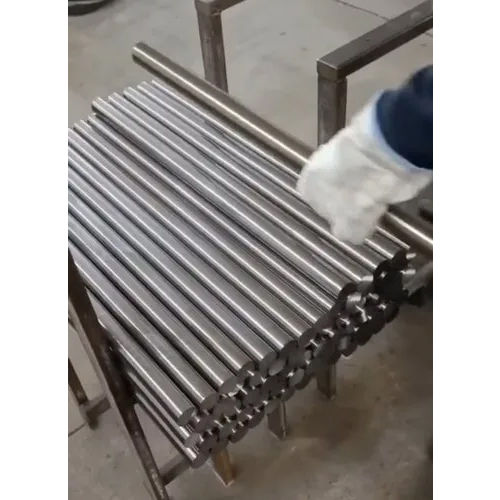

Monel Round Bars

Density : 8.8 Gram per cubic centimeter(g/cm3)

Thickness : Customizable as per requirement

Shape : Other, Round

Melting Point : 1350C to 1390C

Color : Metallic Grey

Strength : High Strength

Monel K500 Sheets

Density : 8.44 Gram per cubic centimeter(g/cm3)

Thickness : Varies (commonly ranges between 0.5 mm to 6 mm)

Shape : Flat Sheets, Other

Melting Point : 13501390C

Color : Silver

Strength : Yield strength of around 800 MPa

Monel K500 Bar

Density : 8.44 Gram per cubic centimeter(g/cm3)

Thickness : Customizable per requirements

Shape : Round/Bar, Other

Melting Point : 13501390 C

Color : Metallic Silver

Strength : High Tensile Strength

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free