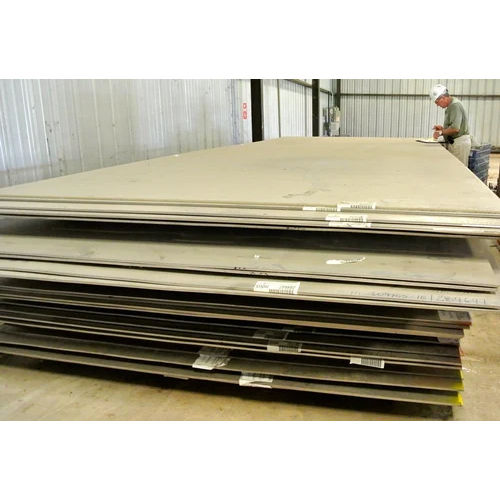

AMS 5599 Alloy 625 Plate

AMS 5599 Alloy 625 Plate Specification

- Hardness

- 95 Rockwell B (HRB)

- Tensile Strength

- 830 MPa

- Thickness

- Varies (Customizable)

- Thermal Conductivity

- 9.8 W/mK

- Product Type

- Plate

- Types of Alloy

- Nickel-based superalloy

- Material

- Alloy 625

- Shape

- Rectangular

- Strength

- Excellent fatigue and tensile strength

- Resistance

- Exceptional resistance to oxidation corrosion and high-temperature environments

- Grade

- AMS 5599

- Melting Point

- 1290-1350C (2350-2460F)

- Density

- 8.44 Gram per cubic centimeter(g/cm3)

- Chemical Composition

- Nickel 58.0% Chromium 20.0-23.0% Molybdenum 8.0-10.0% Iron remainder

- Color

- Metallic Gray

About AMS 5599 Alloy 625 Plate

FAQs of AMS 5599 Alloy 625 Plate:

Q: What are the key features of AMS 5599 Alloy 625 Plate?

A: The key features include excellent fatigue and tensile strength, exceptional resistance to oxidation and corrosion, customizable thickness options, and a high thermal conductivity of 9.8 W/mK.Q: What is the chemical composition of Alloy 625?

A: Alloy 625 is composed of Nickel (58.0%), Chromium (20.0-23.0%), Molybdenum (8.0-10.0%), and Iron (remainder).Q: What is the tensile strength of AMS 5599 Alloy 625 Plate?

A: The plate offers a tensile strength of 830 MPa.Q: What is the hardness of Grade AMS 5599?

A: Grade AMS 5599 has a hardness of 95 Rockwell B (HRB).Q: What is the melting point of the Alloy 625 Plate?

A: The melting point ranges from 1290-1350C (2350-2460F).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Products Category

Inconel X750 Rod

Color : Silver

Thermal Conductivity : 11.2 W/mK

Shape : Other, Round

Melting Point : 13701430C

Strength : High strength under hightemperature conditions

Hardness : Other, Rockwell C32 (Approx.)

Inconel Seamless Pipe

Color : Silver

Thermal Conductivity : 9.8 W/mK

Shape : Other, Cylindrical

Melting Point : 13501400C

Strength : High strength in extreme conditions

Hardness : 22 HRC, Other

Inconel 600 Tube

Color : Silver

Thermal Conductivity : 14.8 W/mK at 20C

Shape : Other, Circular (Tubelike)

Melting Point : 1354C

Strength : High strength across a wide temperature range

Hardness : 8590 HRB, Other

Inconel 925 Rods

Color : Silver

Thermal Conductivity : Low thermal conductivity

Shape : Other, Cylindrical

Melting Point : 1350C 1400C

Strength : High mechanical strength

Hardness : Other, High hardness suitable for industrial applications

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS